OTIF explained: The what, why and how of optimizing for on-time in-full delivery

From the customer’s viewpoint, on-time in full, or OTIF is arguably the most important of the supply chain KPIs, which makes it a vital metric for business success. But what does OTIF actually mean, why is optimizing against it so crucial, and how can you get started?

OTIF meaning: A simple acronym

OTIF is an acronym of on-time, in-full. It refers to a supply chain metric that measures the percentage of orders a business is able to deliver on the date or at the time agreed with the customer (on time) and at the volumes expected (in full). An order can be considered as delivered OTIF if the customer receives exactly what was ordered, in the amount requested, at the correct location, and within the agreed upon timeframe.

Generally businesses use the OTIF rate as a key performance indicator (KPI) against which to measure and optimize their own performance, and the extent to which they are meeting contractual obligations to their customers. But they can also use it alongside other supply chain KPIs to benchmark and compare supplier performance, allowing them to make better procurement decisions.

Why is maximizing OTIF performance so important?

The most obvious reason for improving OTIF compliance rates is customer satisfaction. Customers expect on-time delivery of goods purchased. They definitely don’t want late deliveries and, in many instances, being early can be just as inconvenient. And they ordered particular products in specific amounts for a simple reason — because that’s what they want or need. Of course, there are times when getting half the order today and the rest of it next week will be better than getting nothing at all — but essentially the customer wants their whole shipment to arrive within the agreed upon delivery window.

Getting the products they ordered, at the time they were promised means happy customers. And happy customers mean brand loyalty and advocacy, recurring sales, and revenue growth. On the other hand, a shipper that fails to deliver against OTIF standards is likely to facie to complaints, poor reviews, and customers taking their business elsewhere.

Of course, there are other reasons to pay attention to OTIF metrics. In some sectors OTIF fines and penalties can be applied for failure to meet contractual obligations, and incurring these can quickly erode profits as well as damaging brand reputation. Recent McKinsey research into the North American CPG sector reveals many retailers are tightening their OTIF requirements by narrowing delivery windows and increasing fines, as well as altering definitions of ‘in-full’ delivery. In addition, customers may also seek to recover costs for losses they have suffered as a knock-on result of on-time delivery failure.

What makes OTIF challenging to improve?

Delivering what the customer ordered at the right time doesn’t sound like such a big ask. So what makes OTIF such a challenging metric to improve?

The answer lies in the complexity and fragmentation of the average supply chain. Supply chains are made up of hundreds of individual processes that take place at different times, in different departments. It only takes a small hiccup in one of those processes to disrupt the entire supply chain and adversely affect on-time delivery.

For example:

Unnecessary delivery blocks can delay customer order fulfillment

A stockout could be caused by outdated supplier lead times

A late release from the warehouse could result from a lack of work order prioritization

This situation isn’t helped by the fact that each team or department within the supply chain tends to work in its own silo, with little collaboration or visibility between teams. So any changes in one department can have unforeseen implications both upstream and downstream.

No single department wants to take responsibility for metrics like OTIF, especially where fines and penalties are involved. Instead fingers are pointed at other departments in a phenomenon we call the blame chain. Sales reps faced with angry customers will blame the customer service team, the customer service team will blame the material planners, and the material planners will blame the forecast analysts or procurement team.

Getting started with OTIF optimization

The great news is that hidden within your processes there are opportunities to streamline supply chains and meet OTIF metric targets. Using process mining you can start at any point in the supply chain, unearth these opportunities, and take immediate action to increase efficiency.

Every business is, of course, unique. But there are particular opportunities that crop up regularly across our clients’ supply chains. Let’s take a closer look at three of these opportunities, and how you can use them to improve OTIF.

Increase OTIF by accelerating order processing

Effective order processing is a simple, but highly effective way to ensure orders are delivered at the right time, and in full. Common opportunities to drive smooth and efficient order processing tend to fall into the following categories:

Identify delayed orders: Amend delayed shipments, deliveries, invoices, and orders with changed delivery dates to meet customer expectations.

Investigate blocked orders: Order blocks are often necessary to ensure business requirements are met, but if they are incorrectly placed (say a credit block for a customer that always pays) they can unnecessarily delay delivery and result in poor OTIF.

Detect incomplete orders: Rectify orders with missing information, such as a missing order price, to ensure smooth processing.

There are systems in place to catch the above issues, but the fixes are usually manual, which can slow down order processing, delay delivery, and have a negative impact on your OTIF score.

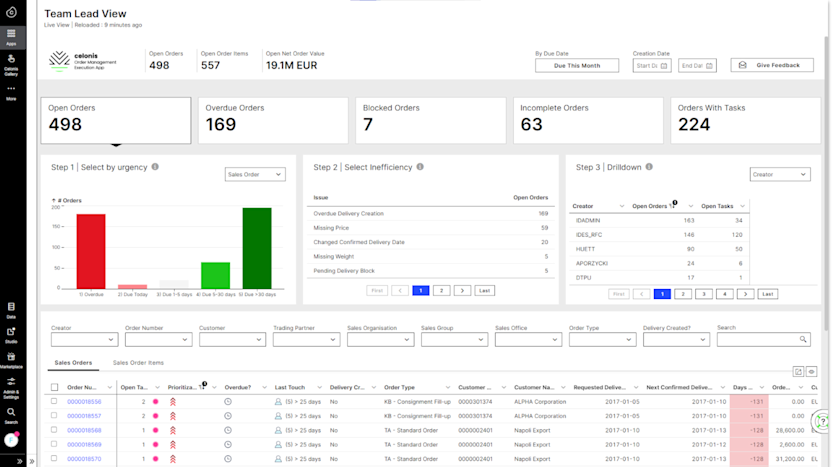

To act on these opportunities to increase efficiency and enable timely processing, Celonis has created the Open Order Processing App. A single app for teams to efficiently process orders, it automatically detects and takes action on the three most impactful opportunities — delayed, blocked and incomplete orders.

In addition to cutting cycle times on order processing by addressing these opportunities, it also increases touchless orders, handling exceptions, prioritizing orders and taking the best prescriptive action.

Improve material availability with up-to-date parameters

Poor material availability has a direct impact on OTIF delivery. One of the most common (and most controllable) causes of stockouts is inaccurate planning parameters such as:

Safety stock and reorder points, which aren’t updated often enough to keep pace with today’s disruptions.

Supplier lead times, which are typically updated manually and are challenging to keep up-to-date, especially if a supplier changes and the material planner is unaware.

Production lead times, which are usually based on the plant manager’s experience, and don’t take into account the latest developments.

There is a huge opportunity to identify and correct these out-of-date planning parameters to better balance inventory levels and ensure the right products are available at the right time to meet OTIF metrics.

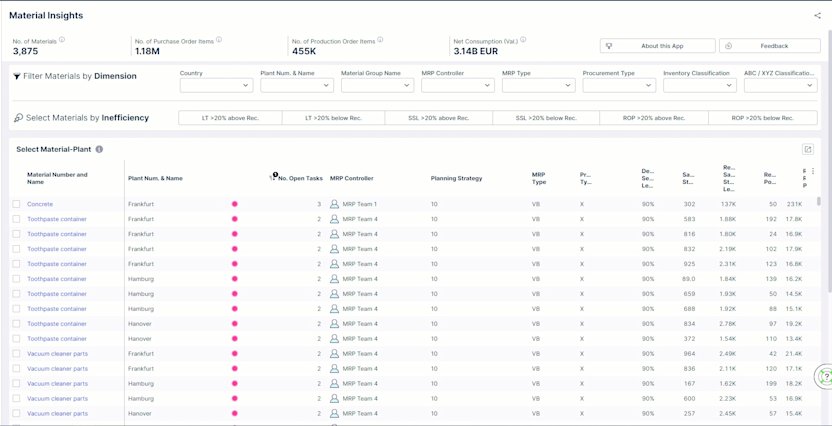

To keep planning parameters up to date and improve material availability (which will ultimately improve OTIF), Celonis has created the Master Data Improvement App. The app uses procurement, order management, production, and inventory data to recommend accurate supplier lead times, safety stock and reorder points. By displaying the details behind the recommendations, the app enables planners to apply their own knowledge to a powerful machine learning algorithm and ensure planning parameters are based on the latest information.

Outsmart shortages based on customer impact

Supply chain performance has been a hot topic in recent years due to the disruptions caused by COVID-19. And, material shortages will inevitably have an impact on the ability to meet OTIF targets. But there are opportunities to reduce that impact and avoid low OTIF through increased transparency and data-driven decision making.

Dealing with material shortages is usually a highly manual and resource-intensive process. A siloed IT landscape means there is limited supply chain visibility which makes it hard to see shortages that are likely to arise across multiple plants, or the overlaps and dependencies of those shortages. Holistic, data-driven decision making, and planning based on shortages that will impact critical revenue is largely impossible and teams have to try to tackle all shortages at the same time.

To effectively manage material shortages based on customer impact, and ultimately minimize the impact on OTIF, Celonis has created the Material Shortages App. The app gives overarching transparency into all critical shortages being faced within a given time period, along with their implications on customer orders. It delivers deep insights on the critical parts with interdependencies and, in the near future, it will allow users to switch between scenarios to get an allocation recommendation for an optimized production plan.

With OTIF having a direct impact on customer satisfaction, it is an important metric to optimize towards when streamlining supply chains. Why not visit the Celonis for Supply Chain webpage to learn more about how businesses can seize the opportunity of process-led supply chain transformation?