How Celonis is Ensuring Supply Chain Reliability in the Time of COVID-19

A few months ago, no one could imagine how SARS-CoV-2 would make the world stand still. Within weeks, the virus has spread to almost every country, infected hundreds of thousands of people, filled hospitals, emptied public spaces.

And it didn't stop there.

Since January, the world has witnessed a wave of city-wide closures, leading to economies in these high-risk countries to come to a complete standstill. Suppliers operating in these countries have either had to shut down factories or increase time to production, resulting in late deliveries to their customers, or missing deliveries entirely.

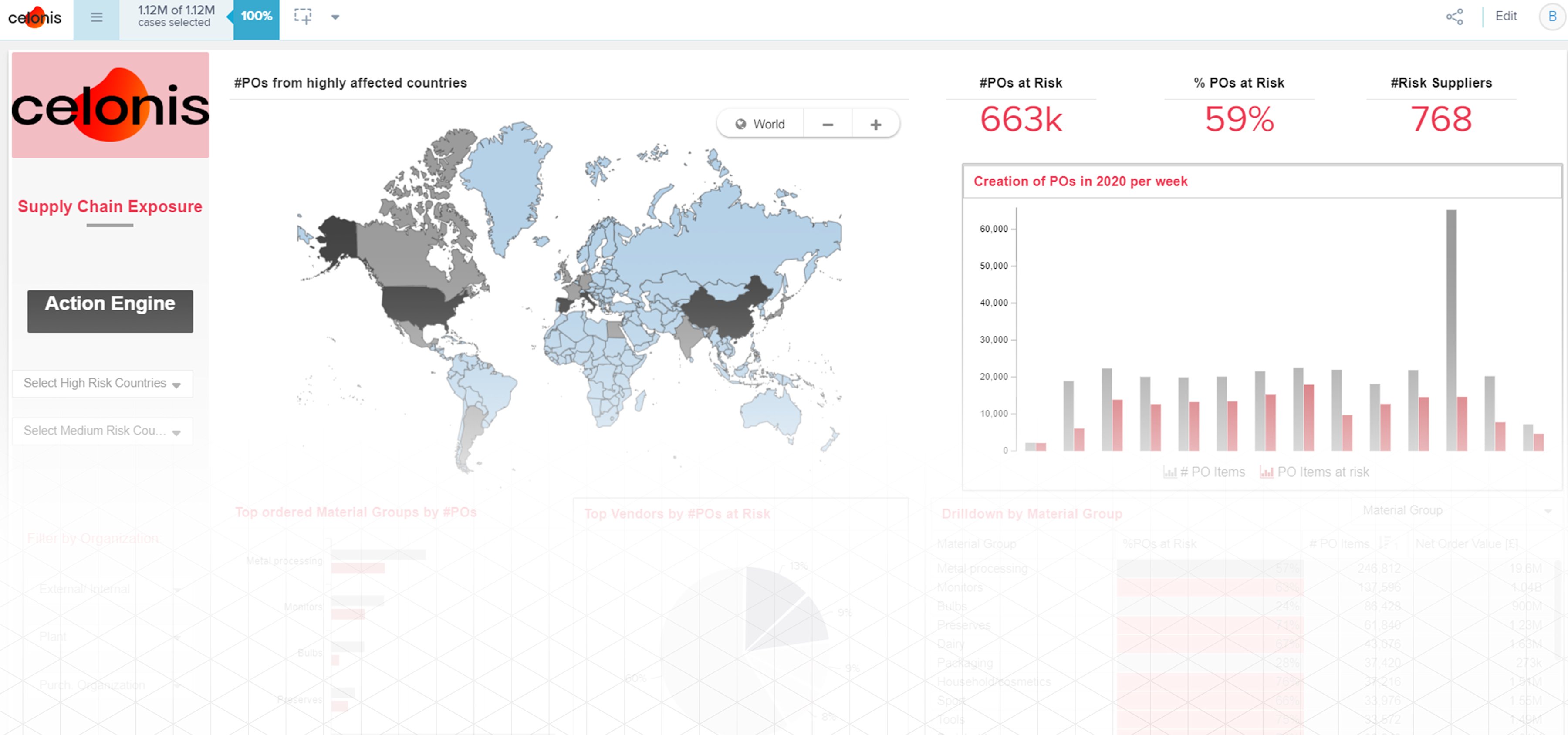

Companies are focused on ensuring the safety and well-being of their employees, not to mention their financial well-being. In order to do so, companies must have complete oversight of their existing supply chain and production process. This involves identifying the suppliers and material movements that may have been affected by COVID-19 and understanding the impact this may have on delivering to their customers on time.

How to Optimize Your Supply Chain

The first step to optimizing one’s supply chain is understanding where it is most vulnerable to disruption. Understanding where high-risk vendors sit throughout the supply chain and how likely it is that goods will be delayed provides clarity around where adjustments need to be made, rather than making onerous adjustments to the overall supply chain. Vendors who typically serve only one region or sit elsewhere in the supply chain can step up to fill capacity, allowing business leaders to make the best possible decisions in such uncertainty.

But what about for the goods already making their way through the supply chain? Staff should be deployed to monitor the supply chain proactively. Continuous alerts, like those in the Celonis Action Engine, keep staff abreast of order status, and can flag any bottlenecks for a task force team to unblock. When possible, have a Plan B (or a solution that prepares one for you), in case the suppliers identified cannot deliver on their order anymore.

Companies have for years been optimizing for fast supply chains, and today’s crisis shows the necessity of resilient supply chains; But what if you could have both? Technologies like process mining enables companies to understand what outcome their processes are optimized for, and with tools like Celonis Process Discovery and Process Analysis, companies can understand how to adjust their processes to drive towards the outcome needed at a particular point of time.

How Celonis Can Help

As the Celonis community has come together, we’ve heard three common use cases of how our customers and prospects are adjusting to these unprecedented times. We’ve taken their feedback and have created three apps for all of our existing customers which support the most common scenarios – two for Cash Preservation and one for Supply Chain Visibility. Versions of these will also be available on our free version of Celonis – the world’s first free and open process mining software - so that members of the wider process community who are facing common challenges can also leverage the benefits of the Celonis technology.

In our recent webinar, you will find out how Celonis can help you to make the best decisions possible in the face of uncertainty by leveraging process mining technology to monitor your supply chain in real time, surface the right data when you need it, and drive immediate action. Watch on demand here.