End-to-end lead times and why they matter to your supply chain

End-to-end lead time is a fundamental KPI for lean supply chain management and, ultimately, for any enterprise that wants to build a robust, efficient, agile supply chain. But, like supply chains themselves, end-to-end lead times contain hidden complexities that make them difficult to understand and optimize. So let’s take a look at this vital metric and why it’s so important to supply chain leaders.

End-to-end lead times explained

End-to-end lead times, sometimes abbreviated to E2E lead times, tell us how long the process takes to create and prepare goods for customer orders. The timeline includes the time it takes to acquire the necessary materials, to move them to production sites, to produce the finished goods, and to send them to the distribution center, ready for customer orders to be fulfilled.

The benefits of optimized lead times

As a snapshot of your supply chain in full, end-to-end lead times are a critical KPI to understand and optimize — and, once you can harness this capability, the benefits are far-reaching.

When you understand end-to-end lead times, you can:

Optimize lead times to reduce working capital and accelerate cash conversion

Find ways to exceed service levels for each customer

Adapt to disruptions while still meeting service levels

Calculating lead times: why is it so difficult?

So understanding end-to-end lead times is a necessary step towards supply chain efficiency, but how do you calculate lead times? With some difficulty, is the usual answer.

Supply chains are multifaceted, highly complex systems consisting of multiple processes across sourcing, procurement, production, transportation, warehousing, order management, and more.

These processes are managed by people in different teams, in different places, using different systems — so supply chain processes are decoupled, meaning there is no direct event-to-event or event-object relationship.

Say you’re a company that sells caps for toothpaste tubes. Your customers need their orders in a week, but it takes you two weeks to source materials and manufacture the caps. In order to avoid stock-outs (and disgruntled customers, because you’ve failed to meet your all-important service levels), you need to keep some inventory on hand to plug any gaps. Enough — but not too much — excess.

Due to the decoupled nature of the toothpaste tube supply chain, the dependent processes cannot be captured end-to-end using traditional process mining techniques, which look at single cases, such as purchase orders and production orders — instead of objects (more on those shortly). As a result, you can’t achieve end-to-end visibility, you can’t understand your end-to-end lead times, and you can’t strike the right balance in inventory management.

End-to-end lead times solutions: the missing element

The missing piece of the end-to-end lead times puzzle, then, is the ability to achieve end-to-end visibility across the decoupled processes in your supply chain.

Business intelligence tools, and supply chain optimization tools in general, haven’t been able to unlock this end-to-end visibility. For more on alternative solutions and their shortcomings, check out our mini guide, Improve end-to-end lead times.

As mentioned earlier, even traditional process mining, powerful as it is, cannot generate a truly end-to-end understanding of supply chain processes. Faced with decoupled process data spread across siloed systems, we encounter some of the limitations of traditional process mining:

Painful data extraction and transformation, which must be repeated

Cases are seen in isolation — one case identifier exists per event — making it challenging to capture the interaction between processes.

Reliance on 2D event logs and models to represent a more complex 3D reality

Supply chain leaders need a new way to calculate lead times, enabled by end-to-end process visibility.

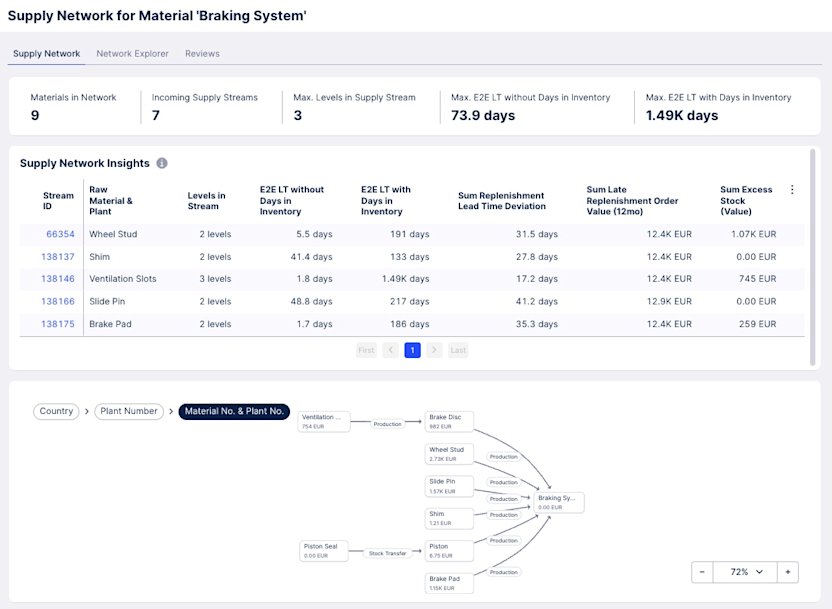

The End-to-End Lead Times App

The Celonis End-to-End Lead Times App unites all the processes, objects, and connections between those objects, required to produce, manufacture and distribute goods in your supply chain.

Celonis End-to-End Lead Times App

The breakthrough that makes this possible is what’s called object-centric process mining, which in turn is enabled by the Object-Centric Data Model. This acts as a single source of truth — a single data model — for all process intelligence, kind of like your organization’s digital twin.

The Object-Centric Data Model opens up greater modeling simplicity and analytics flexibility, as well as faster implementations thanks to the system-agnostic nature of the model across source systems.

With this data model as an expanded foundation, supply chain leaders can now unleash the full power of process mining. By using the End-to-End Lead Times App, they can:

Track the movement and location of components through each and every process required to create a finished good

Surface the finished good with the lowest service level or any finished good with excess inventory, making it easier to improve end-to-end lead times

Identify potential root causes of the end-to-end lead time bottlenecks, so you can take take immediate corrective action

Learn more about how the Celonis End-to-End Lead Times App helps you understand and optimize this critical supply chain KPI.

And explore more topics for your process-led supply chain transformation.