CPG Industry Challenges: Process Mining Could Be the Secret Weapon for Improving the Customer Experience

It’s an interesting time to be a consumer package goods (CPG) company. Not only are consumers more likely than ever to try out new brands, there are more competitors for them to switch to, and we’re still living through a global supply chain crisis.

Want to see the state of CPG in numbers? Check out our CPG infographic.

So customer experience (CX) is more important than ever in maintaining brand loyalty, and CPGs are finding themselves responsible for improving CX in a way they never have been before.

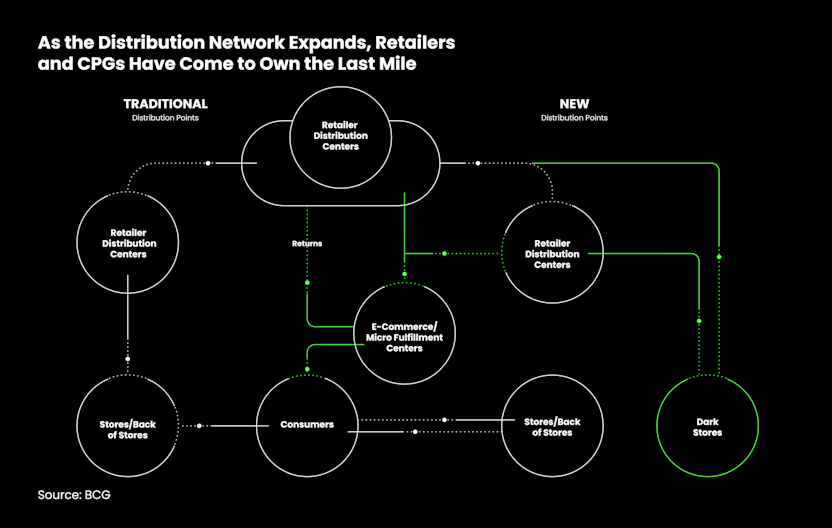

Partly that’s because of the increasing shift to direct-to-consumer (DTC) models, but when you zoom out and look at all the different dependencies and connections that CPG companies are responsible for maintaining now, it’s no surprise that any hidden inefficiencies inside a CPG company directly affect the end customer experience.

It’s an unruly beast, where a single unreliable supplier can leave you in a position where your customers are given no choice but picking up a competitor’s product because yours simply isn’t on the shelf.

The secret to wrestling this particular kraken starts with managing your customers’ orders appropriately.

The secret to CPG success in Order Management

While Order Management isn’t able to control what happens in the rest of the supply chain, it is the customer-facing part of Purchase to Pay.

Which means it’s the place where CPG companies stand the best chance of giving a great customer experience.

But how do you give a great experience when so much is out of your control? In a couple of different ways:

1. Making promises you know you can keep

Right now, the company that keeps its promises keeps its customers. You’re still being held to 2019’s standards of on-time and in-full (OTIF), but the game has changed. If you can’t hit your OTIF targets, the next best thing is managing expectations better than anyone else is able to — and avoiding penalties in the process. Here’s where process mining could help. By getting a real-time x-ray of how your business is operating, you’ll be able to give delivery dates based on your actual supply chain rather than estimates and best practices. But of course, it’s not just about getting things there when you said, it’s also about making sure you’ve got the things to send. Which leads us on to our next point.

2. Avoiding stock outs

Right now, CPG companies are needlessly losing tens (if not hundreds) of thousands of dollars a year on rejected inbound orders due to stock outs when they don’t need to be — and tanking CX in the process. By using process mining, you would be able to instantly know when an order has a stock issue, identify what sort of substitution rules you have in place on that contract, then trigger an action that suggests an alternative. So you don’t lose the sale, and your customer still gets to fill their shelves with products their customers will love.

Getting started with process mining

The first step is connecting the real-time data from your systems to a process mining system. The second step is watching as you fly past all your competitors.

Okay, it’s not that simple. But the results are that impressive.

One of the most common hurdles to adoption of process mining is the disbelief that it’s actually possible to achieve huge impact with relatively little work. That’s why here at Celonis we like to let our customers do the talking for us:

“I want to see Celonis embedded in every section, every region, every function at Mars.”

TJ Young, Head of Process Intelligence, Mars

If you’re interested in finding out more about how process mining could help you deliver great customer experience, check out The Pocket Guide to Excellent Order Management.