How Amplemann Optimized its Purchase-to-Pay Process

Ampelmann has revolutionised transportation of personnel and cargo between vessels and offshore structures. What used to be a hazardous and expensive operation has become as easy as crossing the street with the help of an Ampelmann system. With more than 6 million people and 13 million KG cargo transfers, Ampelmann is the global leader for offshore gangway systems. But being a global leader comes with many challenges. One challenge is striving for efficiency and compliance at the same time. And that can be difficult when parts to improve or repair equipment need to be shipped across open water. In an industry like offshore gangway systems, inefficiency isn’t just costly. It can be extremely dangerous. Ampelmann has multiple vessels stationed at sea, and when something breaks down, the company must order a piece last minute and have it shipped to the right location. Before Process Mining, Ampelmann workers based their systems largely on intuition and maverick buying. To save their workers the trouble of tracking down errors, Ampelmann, headquartered in Delft, got in touch with Apolix to take a closer look at their purchase-to-pay process with the help of Process Mining. The company wanted a system based on actual facts and business priorities, not hunches. For any finance department, data-driven decision making is invaluable. Therefore, Ampelmann was keen to learn more about the underlying drivers of their purchase-to-pay process, with the emphasis on the discovery of their as-is process flow. When the team at Ampelmann saw the data available to them through Celonis, as opposed to the dashboarding they’d been using, they were blown away. These requirements perfectly fit in the business case for Process Mining as Apolix can create a transparent objective image of a process by taking unused data from their ERP system.

The Project Methodology

The purchase-to-pay process at Ampelmann flows mainly through Microsoft Dynamics AX and a couple of external modules. That makes Process Mining an ideal addition. With the help of Celonis Process Mining software, the company can follow a unique case over multiple IT-systems.

Although most users do not realise this, almost every action performed by a user in an IT-system is recorded in a database. That digital trail gives Celonis access to a wealth of useful data, and Process Mining turns that raw data into actionable insights throughout the entire purchase-to-pay process. Every step, from submitting a purchase order to invoice approval and settle date could be traced back several years. Based on all the identified activities and their timestamps, we generated a transparent overview of the entire process flow. Additionally, Celonis enables Ampelmann to add contextual data like vendors and purchased items. Consequently, this context enabled Apolix to perform root cause analyses for drivers behind inefficiencies and non-compliance.

By discussing early results during a Process Mining project, we create extra value to evaluate and establish additional goals. As a result, you can generate a better direction and insights that add more value. For example, a focus point in the purchase-to-pay process can be the realisation of cashflow discounts. In Ampelmann’s case, the main focus remained creating a transparent overview of their as-is process. This included benchmarking the efficiency of the process flow for invoices with and without purchase orders and underlying drivers.

General Findings

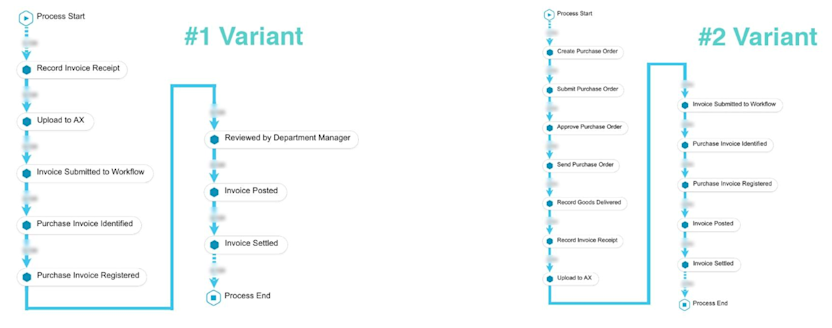

The most valuable findings during this project relate to the transparent overview of the process flow and the analysis performed on the purchase orders. In the image below, you can find the two most common variants of the process, which also describe the desired process flow. After further inspection of the process we found a high number of exceptions. These violations cause an increased amount of process variants, which is undesirable. The majority of these exceptions are found in the invoice approval flow.

Process Mining enabled Ampelmann to visualise that purchase orders often cause these exceptions. Additionally, it showed the company the direct consequences. Combined with the contextual data, we determined underlying drivers such as specific products groups and vendors. Beyond finding these drivers, it supported Ampelmann to create an efficient strategy to overcome these violations. On top of that, we determined the impact on the throughput time and conformance rate of the process. Consequently, we were able to calculate the optimal throughput time when the non-compliance is solved. These numbers support Ampelmann setting realistic goals for optimisation projects.

Purchase Orders

As purchase orders are linked to the majority of exceptions, we delved deeper into their process flow. With the help of Process Mining, Ferenc Meuldijk (Ampelmann’s purchase-to-pay manager) is able to see the impact of purchase orders on the throughput time and isolate the cases with a large impact on the business. A common violation in the process flow is caused by a price mismatch between the invoice and the purchase order. The ability to determine the impact of this violation on the process, strengthens Ampelmann’s position to support problem solving initiatives based on facts rather than intuition.

Manual work

The business case becomes even stronger. The majority of activities performed to clear non-compliance in the process is manual work. One of those activities occurred in over 15% of the cases. In those cases, it was performed twice or more 65% of the time, which indicates mistakes in the manual work. These and similar findings make the impact of mismatches visible and gives clear direction towards solving this problem.

Process Mining is an excellent tool to identify rework, as the process flows goes twice through the same activity. This means an activity has been performed, but for some reason it has to be done again. Identifying and solving the root causes boosts the throughput time of your process and saves significant manual work. Another example of rework at Ampelmann is invoices which get stuck in the workflow, are cancelled and re-submitted. By analysing for rework at the activity ‘invoice submitted’ we have been able to identify stuck invoices and the impact on the process flow.

It is amazing to finally have your gut feeling confirmed, from now on we can make decisions based on facts rather than intuition! – Nazanin Hosseini, ERP Business Consultant @ Ampelmann Operations B.V.

Next Steps

The findings from the project indicate the importance of improving the quality of the purchase orders. Even though Ampelmann has an outstanding throughput time, much manual labour can be prevented. This will result in higher process compliance, efficiency and time within the finance team for other improvement projects.

As a result, Ampelmann gained a transparent overview of the current state of its purchase-to-pay process. The effect of previous and running projects can now be assessed and a clear direction to improve the process is laid out. Based on this snapshot, a new Process Mining project in the future will give a clear understanding of the progress of the improvement initiatives and enables Ampelmann to set new priorities.