Master Data Improvement: Keep your planning parameters up to date against today’s supply chain and demand volatility

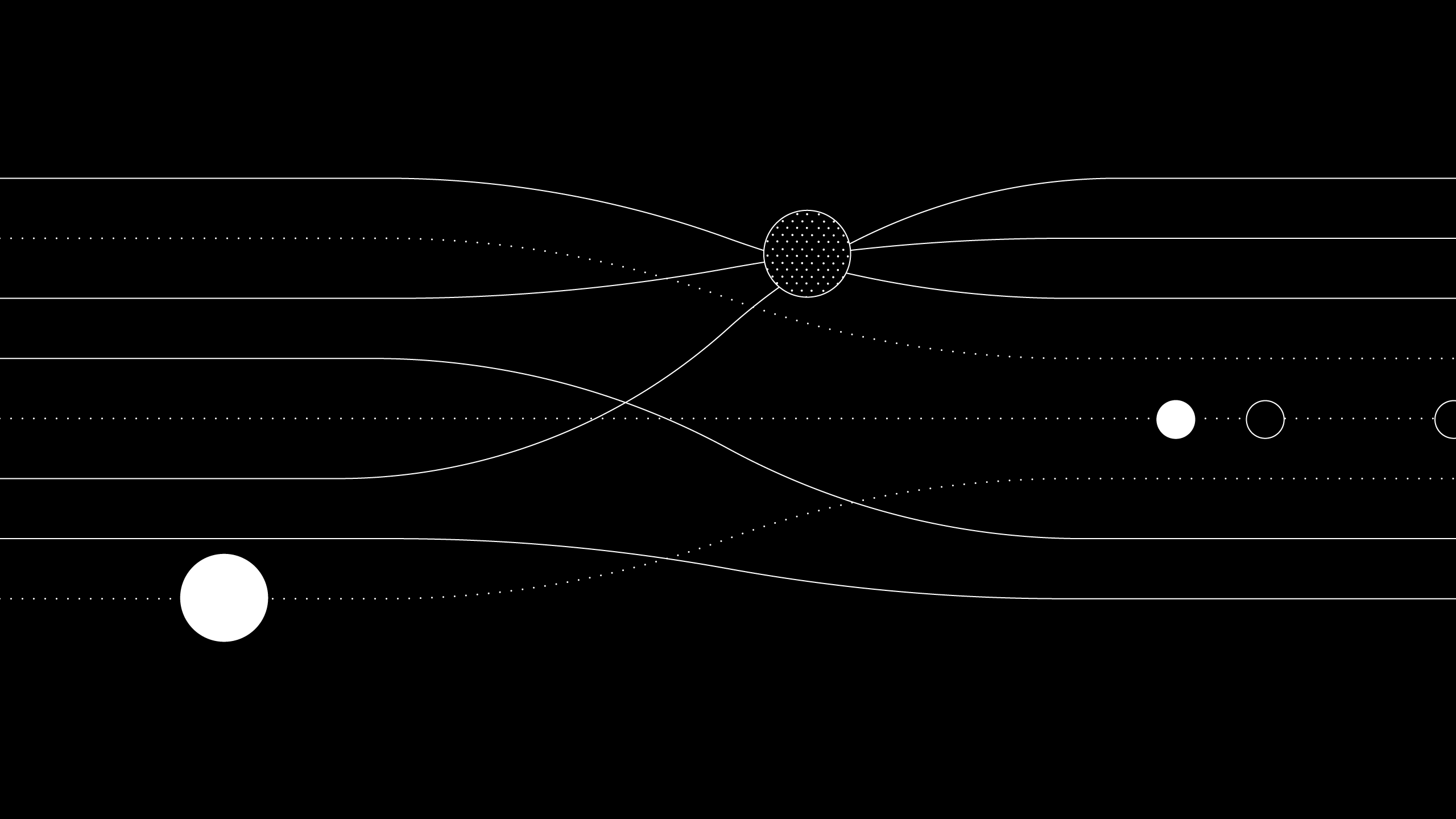

Supplier lead times, safety stock levels and reorder points are crucial to ensuring you have the right material at the right time to meet your service levels and minimize excess inventory. But with unprecedented shutdowns, geopolitical tensions and more affecting both replenishment and consumption patterns, it's both incredibly challenging and crucially important to keep your planning parameters up to date in order to - build a resilient supply chain.

“We have to rethink supply chain,” said Julian Fischer during a presentation to business leaders at Celonis World Tour 2022. “We have to rethink how we run our operations and how we serve our customers globally,” he added.

This is where the Celonis Master Data Improvement Application comes in.

The Master Data Improvement app uses procurement, order management, production, and inventory data to recommend accurate supplier lead times, safety stock and reorder points using a powerful machine learning algorithm. The app displays the details behind the recommendations, allowing the material planner to apply their own knowledge to Celonis’ powerful machine learning algorithm, and simulate parameters to ensure planning parameters are up to date with the latest information.

This purpose-built solution helps material managers and MRP controllers maintain the crucial parameters across all of their SKUs enabling them to better balance inventory levels to meet customer satisfaction and working capital objectives.

1. Material view at the transaction level: Start with a view of your entire list of materials from multiple SAP ECC instances categorized by lead time, safety stock, and reorder point deviations.

2. Lead time, safety stock and reorder point recommendations: Machine Learning driven lead time recommendations to eliminate biases introduced by the ordering process. Safety stock and reorder point recommendations are based on the recommended lead times, actual consumption and replenishment patterns gathered from order management, procurement, production, and master data.

3. Consumption and lead time validation at a transaction level: Easily assess the recommendations made for each material by reviewing all the transactions tied to the material, their lead times, and consumption levels.

4. Safety stock and reorder point simulation and write back: Calculate a new recommendation using both our recommendation and your own consumption, lead time, service level, and standard deviation assumptions. Write back the recommendation you choose directly into the ERP.

Get started with the Master Data Improvement app and reach out to your Customer Value Manager or Account Executive.

Also see: Why optimizing truck pickup, delivery processes are so important | See Webinar: Are Your Processes Keeping You From Filling Your Trucks On Time? | These 8 characteristics of resilient supply chains can give your business a competitive advantage