Why optimizing truck pickup, delivery processes are so important

Optimizing truck deliveries has become a priority for any enterprise shipping goods. After all, the business value in the processes behind pickup-to-delivery is obvious given inflation and global supply chain issues.

Idle and late shipments, manual processes and half-filled trucks are all things keeping C-level executives up at night over cost and increasing emissions. Here's why shipment execution and optimizing last-mile delivery is moving to the forefront.

What is sustainability in business? The process, returns, KPIs and everything you need to know

Time is money. UPS CEO Carol Tome said on UPS' second quarter earnings conference call that the company's integrated network is sometimes a little off with feeder arrivals and departures. Improving that choreography is the goal of an effort UPS calls Total Service Plan, which will run the company's integrated network "the way it was designed to run." The initiative kicked off July 11, but the real money comment from Tome was this: "A 10-minute improvement within the integrated network is worth $257 million."

Key metrics: On-time delivery, on-time pick rate, picks per hour.

Automation reduces friction. The more truck-related processes can be automated the more efficient they will become. UPS is aiming to eliminate all manual scans. The company is also looking to cut the "tens of thousands of misloads that occur every day," said Tome. Those misloads wind up requiring additional work.

In addition, manufacturers, especially those that specialize in bulky and heavy goods, are optimizing processes to be more low touch and streamlined. Customer and market changes in orders require real-time data to know what's going on a truck and when. If those processes are handled manually there are often more order holds, truckloads and rework. Using something like Celonis Action Flows within the Execution Management System can help with process routing.

Key metrics: Automation rate of order creation, picks per hour, manual scan rate.

See Webinar: Are Your Processes Keeping You From Filling Your Trucks On Time?

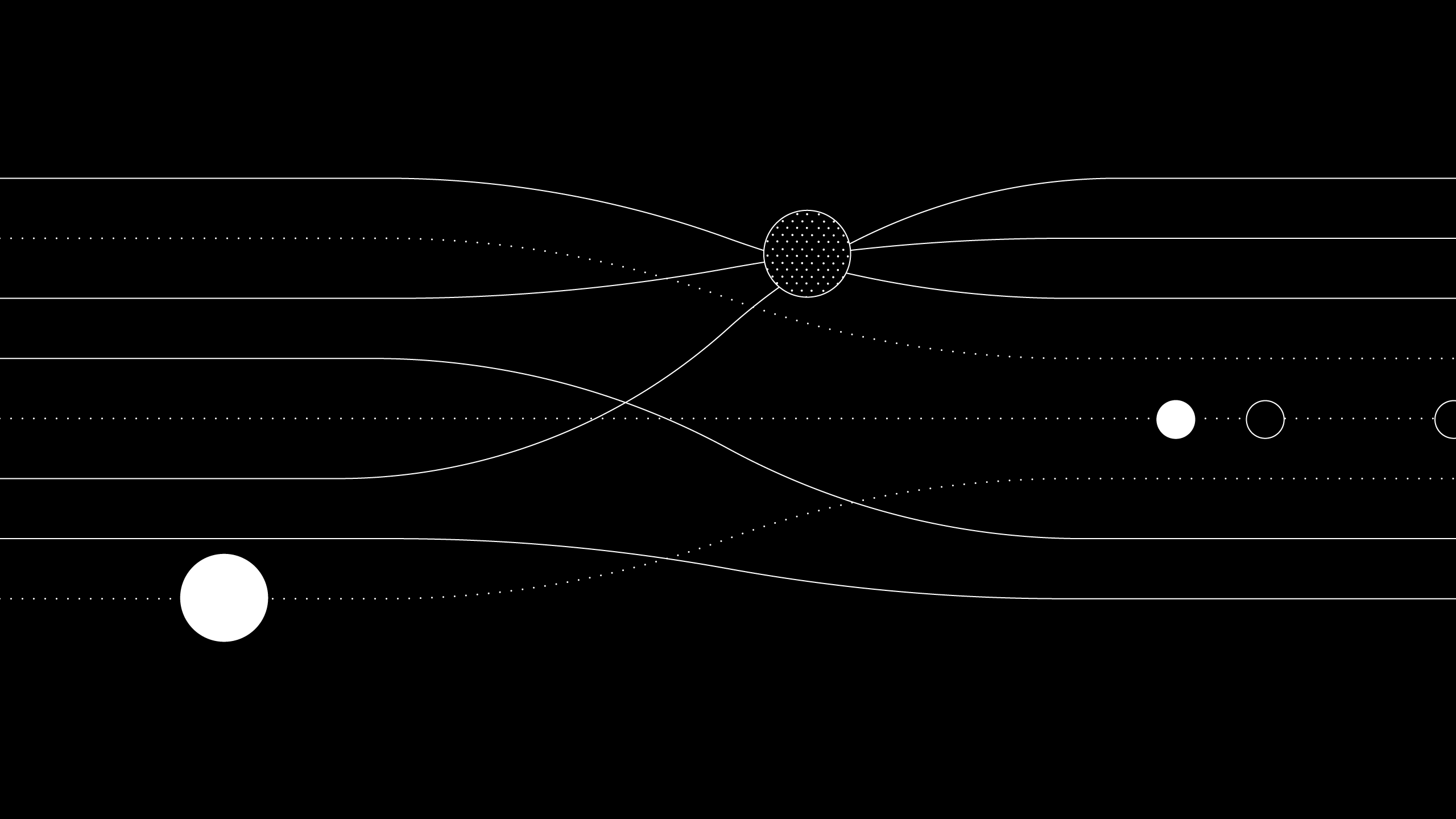

Delivery density improves mile optimization. For any company delivering goods, density and last-mile optimization matters. If you can make two truckloads instead of three you save time, money and Co2e. Improving delivery density requires a 360-degree view of adjacent processes including order management and supply chain so it's easier to group orders.

Tome outlined a pilot with a third-party technology company that powers order management systems for most retailers. The pilot matches orders going to the same address to improve density, said Tome.

"Just to make this real for you, and this is just an estimate, but we estimate the cost of last mile for us is $5.50. That incremental package cost us $0.60. Imagine the value that can be released if we improve the density. We're going to give some of that value back to our customers," said Tome.

FedEx is planning to coordinate its delivery networks such as FedEx Ground and FedEx Express to optimize last mile delivery. Richard Smith, Regional Vice President of The Americas, and Executive VP of Global Support, outlined some of the early success with Last Mile Optimization (LMO). "Rather than duplicate last mile routing footprints across these 2 parcel networks, LMO created the insight and processes to effectively hand off packages between networks and remove redundant routes," said Smith.

Density on trucks also matters for speed, which improves customer satisfaction. Amazon CFO Brian Olsavsky said the e-commerce giant is improving its expanded fulfillment network. "On the transportation side, we continued to improve delivery, route density and improved package deliveries per hour," he said. "We are encouraged by the progress during the quarter and see opportunity to further improve in the second half of the year."

Key metrics: Shipment capacity utilization, shipment changes, consolidation rate of similar orders.

More supply chain:

These 8 characteristics of resilient supply chains can give your business a competitive advantage

Global CEOs aim to bolster supply chain resilience amid inflation, recession worries

Optimizing your logistics and the processes behind truck utilizations improves sustainability. While sending out two trucks instead of three for deliveries saves money on fuel and labor, it also advances the sustainability cause. Supply chain optimization and sustainability are closely linked and given inflation lower costs and emissions have never been more aligned.

Janina Nakladal, Director of Sustainability at Celonis, said at Celonis World Tour 2022 Houston that process excellence, efficiency and sustainability are converging.

"The cost increases of transitioning to net zero are lower than they were due to inflation," said Nakladal. "It will be efficiency plus sustainability that will get you performance."

Key metrics: Shipments with quantified emissions, reduction in Co2e.

More sustainability: